Cut unwanted machine downtime

Connected Workers keep your machines running as efficiently as possible.

Cut unwanted machine downtime

Machine downtimes. Resolved in record time.

Reduce machine downtimes

by alerting operators in

real-time

Increase overall equipment effectiveness by shortening reaction times

Accelerate resolution times by giving workers personalized guidance

Connected Worker app bundle designed for machine operations

More efficient processes, fast resolution, reduced machine downtimes

A better way to operate machines

Our Connected Worker apps are completely adaptable to your specific processes. The

Workerbase solution can be fully integrated into your existing IT infrastructure whether you`re

working on-premise or in the cloud. All apps work seamlessly together in a one-stop-shop. Start

with one app for a single production line, or configure multiple workflows for your entire factory:

we`re here to help you get up and running fast so you can reap the benefits of Connected Worker

app-based workflows immediately.

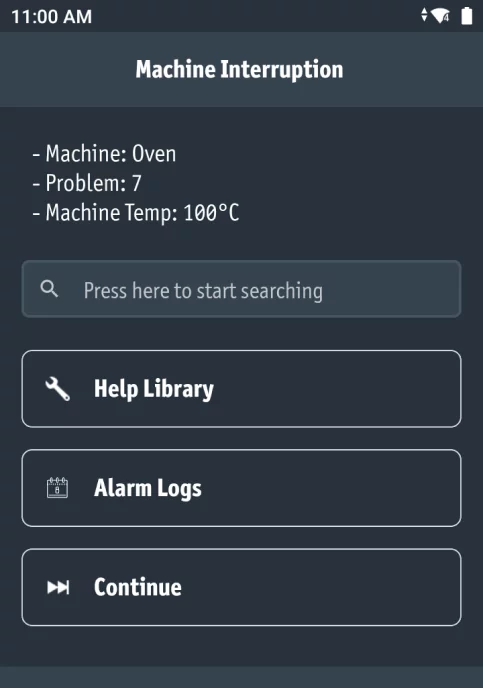

Machine alarms

You can start using our software within a few days, without impacting your production environment. No downtime. Instant value.

Machine changeovers

Walk teams through processes with customizable checklists. Keep track of critical steps and reduce mistakes. Improve first pass yield and maintain industry standards effortlessly.

OEE data collection

Collect machine and quality data directly from the shopfloor. Using customizable data input forms for smartwatches and smartphones, operators can efficiently feed back error codes and other missing data points from their personal device.

Andon support calls

Allow operators to efficienctly send Andon request to shorten reaction times and remove bottlenecks. Popular use cases include monitoring machine downtimes, creating material requests, and calling for support.

Non-conformities reporting

Identify non-conformities early on and notify the relevant people in real-time using emails or smartphone notifications.

…and more!

Use the Workerbase platform as a blank canvas to configure any workflow you need with complete flexibility.

Machine Operation Apps: your benefits

Shorter response times

Tasks get assigned to the right person at the right time based on configurable business rules. This skill-based distribution reduces response times drastically.

Clear and consistent reporting

All machine operation workflows provide detailed information for precise issue reporting such as Missing material, Amount: 50, Type: Broken shafts, and Charge: 2364.

Prevent multiple people chasing the same issue

Real-time insights enable proactive issue resolution and process optimization, driving continuous improvement.

Fully integrated digital environment

All machine operation Connected Worker Apps work seamlessly together and integrate with existing machines and systems (ERP, MES and more).

Example workflow

The workerbase system is a fully configurable digital platform that can be meet you individual requirements. This is what a typical deployment process looks like.

Step 01

Connect your machines

The Workerbase connector framework allows you to connectany kind of machine or system. Whether you want to connect to the machine’s PLC controller directly, use an IOT gateway or send alarms by email or out of your MES system, we

support all types of connection mechanisms and protocols.

Connections are bi-directional, so as long as there’s an

interface, you can send acknowledgements or repair results

to your existing systems.

Step 02

Send real-time alerts to your operators

Your workers are equipped with digital devices such as smartwatches

or smartphones, and you start saving precious time from day one.

Alert your operators in real-time on their personal smart devices and

immediately initiate corrective actions. Each alert sent to your staff

gets the problem solved quicker, thereby reducing machine downtime.

Step 03

Predict machine failures

There are many ways to predict machine disruptions. Workerbase can enhance the quality of those prediction by feeding you additional data from human operations. Tracking the time and nature of repair on top of the basic failure data significantly increases the accuracy of your predictions. By monitoring critical machine parameters and adding human generated data, you can prevent machine failure by alerting frontline staff even before disruptions occur.

CURIOUS TO TRY?

Ready to chat?

Your factory. Without disruptions.

Increase throughput

Reduce quality costs

Improve productivity

Trusted by the world’s largest manufacturing companies